Challenge Us

Discuss Your Requirements

Dovetailed Sheeting

Challenge Us

Discuss Your Requirements

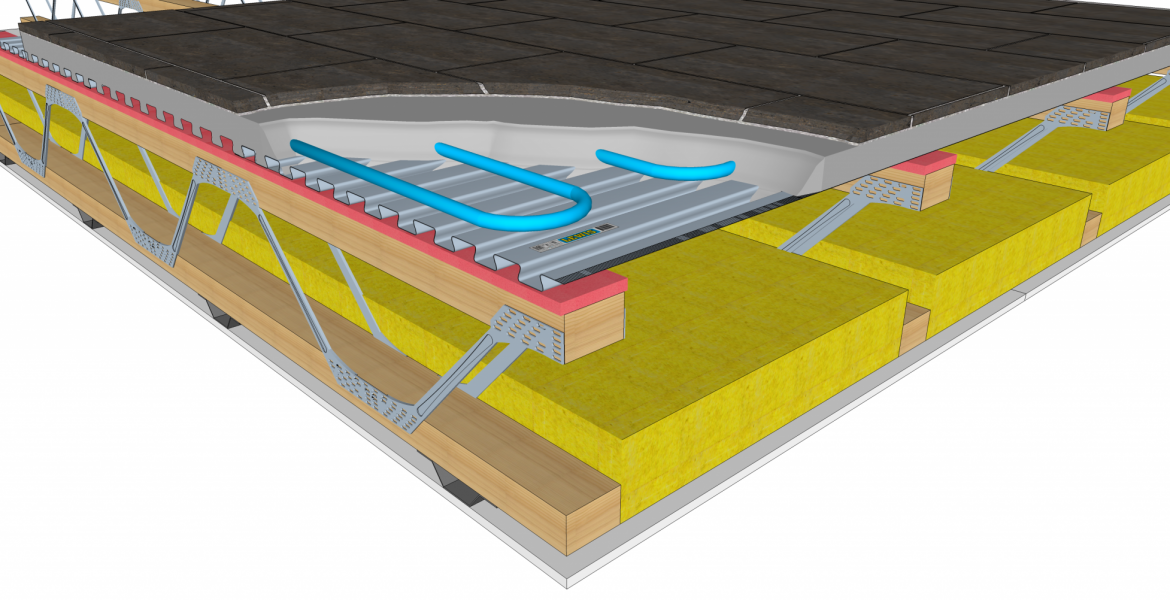

LEWIS Dovetailed metal decking, as part of a joisted floor system, provides a first class solution where acoustics and fire protection are key concerns.

Insulated Floor and Roof System

Challenge Us

Discuss Your Requirements

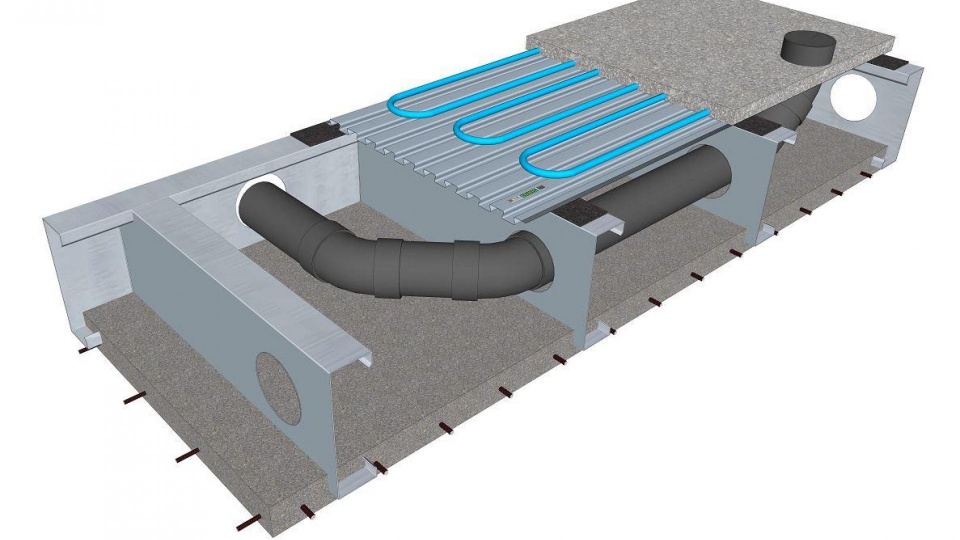

Op-Deck, high-load-bearing concrete roofs and floors.

Car parks, green roofs and terraces.

Profiled Sheets

Challenge Us

Discuss Your Requirements

Hody Decking is a trapezium shaped metal profile deck of 60 mm in height for slim composite floors

Reinforcing Sheets

Challenge Us

Discuss Your Requirements

Existing floor strengthening, stiffening and levelling that can also include underfloor heating, from just 15mm in depth.

Ground Floor System

Challenge Us

Discuss Your Requirements

An ideal solution to replacing old, rotten timber ground floor joists that gives a high insulation value and with Lewis Deck on top allows you to have a concrete floor rather than a timber one.

A lightweight floor with a large span and strength

Challenge Us

Discuss Your Requirements

CDI Innovative Construction Materials Ltd (CDI).

Here at CDI Innovative Construction Materials we provide a range of innovative domestic and commercial concrete floors. These are high performance structural floor systems that can be laid on timber or steel joists, providing floor reinforcement, wet room systems, underfloor heating, insulated concrete roof & ground floor systems for high load bearing situations. These are suitable for all types of construction from residential to industrial from new built to renovations.

If you are planning a project that requires a new floor and you are wanting more than the average timber deck that over time will become noisy, move and eventually degrade then please get in touch. Let us talk you through what our systems are all about and how they will improve the feel, strength, performance, and heating efficiency of your floor.

As a small family business we are focused on ensuring that we provide you with the best possible service. So please browse through our website then get in touch with us and discuss your requirements and needs. If you have drawings please send them through, we are happy to do “takes offs” from them to calculate the materials needed and then send you fully itemised quotations.

We are often exhibiting around the UK at various times of the year at trade shows so please have a look at our “Events and Exhibitions” page to see if we will be local to you in the near future.

for self build & renovations

Here is a full list of all of the systems that we have.

for self build & renovations

Here is a list of all of the applications our systems have.

From the minute we initially contacted CDI, regarding the project that we were planning, they were happy to talk to help us and identify where their systems would benefit what we wanted to build. Even though it took us over a year to go from design stage to the build phase they were always available to get advice from to ensure we got the best floor we could.

CDI's systems are suited to all types of construction methods from fast-track, lightweight offsite building methods including timber frame, light gauge steel frame, structurally insulated panel (SIP) systems, insulated concrete formwork (ICF) to all traditional methods of construction such as brick/ block as well as steel frame and other build methods.

Self Build & Renovations

CDI 2024

Cow Close Barn with Heat Pump and Underfloor Heating

01st January 1970

Paul M contacted us in early 2022 to discuss the use of the Lewis Deck system following a recommendation by his Ground Source Heat Pump system installer. We worked through the drawings and provided a quote, the Lewis Deck and…

View All

2022 Has Begun and Exhibitions Are, Fingers Crossed, Back To Normal.

21st January 2022

Starting on Friday 28th January, now that COVID has magically disappeared, we are heading back on the road and will be exhibiting for a full year for the first time since 2019. Next Friday sees the first exhibition at the…

View All

Lewis Deck Brochure Content

01st January 1970

As part of a joisted floor construction, LEWIS® Dovetailed metaldecking provides a first class solution for ACOUSTICS, FIRE PROTECTION and workswell with UNDERFLOOR HEATING AND COOLING systems.LEWIS® Dovetailed metal decking solutions are used in a range of applications includingrenovations and…

View AllChat Live

Website by Indigo