- Home

- About CDI

The Lewis Deck has been picked up by a number of magazines over the years, here is the latest mention in a discussion about underfloor in the Real Homes Magazine:

Underfloor heating: your questions answered

Thinking of installing underfloor heating? Real Homes has posed your most-asked UFH questions to industry experts

Wet vs dry systems

As electric systems are installed directly under the floor covering, and work independently from your central heating system, they are particularly useful for one-room installations or where the sub-floor level is already set. The wire or matting systems are very thin (around 3mm) and shouldn’t cause problems with differing floor levels – thus creating little disruption to the existing room.

Wet systems circulate warm water through plastic pipes installed underneath the floor and are connected to the main central heating source. This system tends to work best when the pipes are embedded in a screed, as this helps dissipate the heat, so it is suited to new floor constructions where the sub-floor can accommodate the pipework and cement screed. Wet systems are therefore more likely to be used in new-builds and extensions or during major renovation work.

Efficiency

Wet underfloor heating (UFH) systems generate temperatures of around 40°C to 65°C, meaning that the actual floor temperature will be on average between 23°C and 32°C. This is actually lower than a standard radiator, so your household heating costs should be reduced over time.

Ease of control

Specialist UFH controls are vital to ensure comfort, responsiveness and energy efficiency. UFH takes longer to heat up and cool down compared to radiators, so to overcome this time lag, programmable controls are essential.

For households with irregular or limited occupancy and for holiday homes, it is useful to have remote control so that you can turn it on an hour or two before arriving. Remote control is also useful if you forget to turn the heating off.

Getting the right insulation

Underfloor heating will always be more efficient and cost-effective when fitted above insulation, as this reduces downward heat loss and forces heat up into the room where it is wanted. In new-build homes and extensions, floor insulation will be incorporated to meet Building Regulations, while on refurbishment projects insulation can usually be added.

Taking up existing floorboards to add insulation between the joists is fairly straightforward. Adding insulation to a concrete screed floor, however, will mean that the height of the floor is increased so skirting boards and doors will have to be adjusted accordingly. We always recommend speaking to a reputable company, as they will be able to offer advice based on the individual characteristics of your home.

Choosing flooring

Solid floors, including stone, porcelain, ceramic, terracotta and slate are ideal, as they tend to have great thermal conductivity and will provide good heat output when it comes to underfloor heating. If you prefer timber flooring, always check with your supplier to ensure it is suitable for use with underfloor heating, or consider engineered timber boards that, due to their construction, tend to be more stable during changes in temperature.’

In both cases, bear in mind that temperatures shouldn’t exceed 27°C. Most top-of-the-range laminates can also be used with underfloor heating, as can all carpets — although you may find heat output is slowed down a little, due to the combination of carpet and underlay.

Potential faults

The main cause for concern for many prospective buyers of warm water underfloor heating is what to do if the pipes leak. However, unless a nail is accidentally put through them at some stage, this simply does not happen. There are no joints in the floor and the various pipes used are designed and tested to have a 50-year life expectancy at temperatures and pressures that exceed those required by the system.

If accidental damage should occur, then individual pipes can be pressure tested to locate the correct one. In timber floors, the pipe can usually be exposed to allow for repairs, while screed floors will need to be excavated to uncover the pipe.

Choosing the right system

It’s particularly effective for large open-plan spaces – particularly those with high ceilings – as the entire floor radiates heat upwards so you benefit from warm feet and even room temperatures. This radiant heat also means reduced draughts, moisture levels and airborne allergens.

Typically underfloor heating is more than enough as a stand-alone form of heating. However, its capabilities will often be dictated by other factors, such as floor coverings and a building’s insulation levels (especially walls and windows). This is why heat-loss calculations are so fundamental, as having looked at a building’s individual thermal performance they will tell you how much heat you need to generate.

For example, a poorly insulated room with lots of glazing may not heat fully when it is cold outside (which means additional insulation or supplementary heating may be necessary). Floor coverings also play an important role. Normally, stone and tiles are excellent options, as are carpets with suitable tog ratings. If you’re keen on timber, however, remember it has a lower temperature tolerance.

Underfloor heating vs radiators

Where cost is an issue, the expense of installing underfloor heating may outweigh the advantages, especially if it involves removing concrete floors and re-screeding. In houses not occupied during the day, underfloor heating’s slow warm-up and cooling time (which can be up to four to six hours) may not suit you.

‘A combination of both systems can often be the best answer for many homes, as radiators can be easily incorporated into an underfloor system. A good compromise is to install underfloor heating on the ground floor, with radiators upstairs to accommodate the different requirements for living and sleeping spaces, especially as many people still want heated towel rails in their bathrooms.’

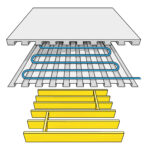

If you’re installing underfloor heating at first-floor level and won’t be laying screed, you can use a steel Lewis Deck as a base. This helps spread the heat quickly across the whole of the floor and further improves its efficiency.

The questions posed within the magazine

- Should I install a dry or wet heating system?

- Can I install underfloor heating in an older home?

- Will underfloor heating add to the cost of my energy bills?

- If I install underfloor heating, should I insulate underneath it?

- Will I be able to install underfloor heating myself?

- What type of flooring is best to lay over the top of underfloor heating?

- What would happen if my underfloor heating developed a fault?

- Is underfloor heating enough to heat a large open-plan space?

- When would it be more cost-effective to have radiators?

- Should I invest in an extended warranty for my underfloor heating?

Case Studies

Self Build & Renovations

FAQs22

Ask CDI a Question

Ask CDI a Question-

Q

What are the Lewis Deck sheet sizes?

AQ: What sheet sizes are held in stock for delivery within a few days after order? A: We stock 2500mm and 1300mm sheets. These are all 630mm wide and 16mm deep. Deliveries are made via the pallet network directly to site. The smaller sheets are aimed at small bathroom renovation projects and can be supplied in small numbers via TNT. 2.5* and 1.3m sheets allow for the 100mm overlap to occur over a joist, with joist centres being either 300mm, 400mm, 600mm, 800mm*, 1200mm and 2400mm*. (*2.5m sheet only) For larger projects we are able to produce bespoke sheet sizes if required, please get in contact to discuss other options for sheet sizes.

-

Q

Why don't my Lewis sheets interlock like they do in the video?

AQ: Why don't my sheets interlock like they do in the video? A: The sheets have two sides (one printed, one plain), the dovetails on either side are different widths, it is then necessary to alternate the sheets print up and then print down.

QIs this a question?

AIf it is, this is an answer.

Latest Blog

CDI 2024

Cow Close Barn with Heat Pump and Underfloor Heating

01st January 1970

Paul M contacted us in early 2022 to discuss the use of the Lewis Deck system following a recommendation by his Ground Source Heat Pump system installer. We worked through the drawings and provided a quote, the Lewis Deck and…

View All2022 Has Begun and Exhibitions Are, Fingers Crossed, Back To Normal.

21st January 2022

Starting on Friday 28th January, now that COVID has magically disappeared, we are heading back on the road and will be exhibiting for a full year for the first time since 2019. Next Friday sees the first exhibition at the…

View AllLewis Deck Brochure Content

01st January 1970

As part of a joisted floor construction, LEWIS® Dovetailed metaldecking provides a first class solution for ACOUSTICS, FIRE PROTECTION and workswell with UNDERFLOOR HEATING AND COOLING systems.LEWIS® Dovetailed metal decking solutions are used in a range of applications includingrenovations and…

View AllChat Live

Hi you're speaking to Dave, how can I help.Website by Indigo

This website uses cookies. To see how this affects you, please read our cookie policy.

If you’re installing underfloor heating at first-floor level and won’t be laying screed, you can use a steel Lewis Deck as a base. This helps spread the heat quickly across the whole of the floor and further improves its efficiency.

If you’re installing underfloor heating at first-floor level and won’t be laying screed, you can use a steel Lewis Deck as a base. This helps spread the heat quickly across the whole of the floor and further improves its efficiency.