- Home

- About CDI

Insworke Mill Quay

Insworke Tidal Mill was originally built around the 1590’s and survived as a working Mill until just before the First World War.

It then had a chequered life as various storage and manufacturing uses until it fell into total disrepair. It went under a major refurbishment and rebuild programme in 2011 to find a new life as a commercial property to the ground floor and residential to the upper floor.

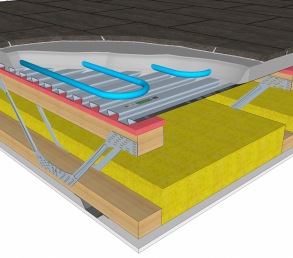

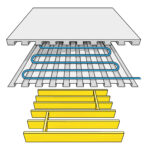

The client turned to a Lewis Deck / screed solution when looking for solve the problem of acoustic and fire separating floors that would allow the new timber beams to be left exposed from beneath to replicate the original beams. On the ground floor Lewis was used to in a similar way to create a warm floor above the voided cellar areas. Lewis Deck on resilient strips was placed on to the new beams with a flanking strip around the perimeter. Underfloor heating was then fixed to the Lewis Deck before the screed was laid giving an overall depth of deck, underfloor heating pipes and screed of just 52mm.

The system is often used in this way in listed buildings such as this to preserve the existing structure and upgrade the performance of the floor. As the floor is laid as a floating structure, that is, without connecting it to the existing timber, it doesn’t damage it and if required, could be removed in the future to bring the floor back to its original state.

Various timber floor structures at Insworke Mill including exposed timber ceilings Exposed timber ceilings at Insworke Mill Quay The renovated Insworke Mill will provide commercial space to the ground floor with the first floor used as residential space for the Newton family.

More recently it was then converted into a Bed and Breakfast and now it is simply a residential property demonstrating the versatility and future proofing of using a floor that allows for these changes of use. If the property comes up for sale in the future it would be simple to put it back to work as any of these uses.

A fabulous project to have been involved with in a beautiful location.

Learn more about the Lewis Deck System here.

Lean more about the Lewis Deck System and underfloor heating on upper floors here.

Barn conversion reflected on the water in Cornwall Wetroom Floor at Insworke Mill Quay in Cornwall Engineered Timber Flooring over underfloor heating Case Studies

Self Build & Renovations

FAQs22

Ask CDI a Question

Ask CDI a Question-

Q

What are the Lewis Deck sheet sizes?

AQ: What sheet sizes are held in stock for delivery within a few days after order? A: We stock 2500mm and 1300mm sheets. These are all 630mm wide and 16mm deep. Deliveries are made via the pallet network directly to site. The smaller sheets are aimed at small bathroom renovation projects and can be supplied in small numbers via TNT. 2.5* and 1.3m sheets allow for the 100mm overlap to occur over a joist, with joist centres being either 300mm, 400mm, 600mm, 800mm*, 1200mm and 2400mm*. (*2.5m sheet only) For larger projects we are able to produce bespoke sheet sizes if required, please get in contact to discuss other options for sheet sizes.

-

Q

Why don't my Lewis sheets interlock like they do in the video?

AQ: Why don't my sheets interlock like they do in the video? A: The sheets have two sides (one printed, one plain), the dovetails on either side are different widths, it is then necessary to alternate the sheets print up and then print down.

QIs this a question?

AIf it is, this is an answer.

Latest Blog

CDI 2024

Cow Close Barn with Heat Pump and Underfloor Heating

01st January 1970

Paul M contacted us in early 2022 to discuss the use of the Lewis Deck system following a recommendation by his Ground Source Heat Pump system installer. We worked through the drawings and provided a quote, the Lewis Deck and…

View All2022 Has Begun and Exhibitions Are, Fingers Crossed, Back To Normal.

21st January 2022

Starting on Friday 28th January, now that COVID has magically disappeared, we are heading back on the road and will be exhibiting for a full year for the first time since 2019. Next Friday sees the first exhibition at the…

View AllLewis Deck Brochure Content

01st January 1970

As part of a joisted floor construction, LEWIS® Dovetailed metaldecking provides a first class solution for ACOUSTICS, FIRE PROTECTION and workswell with UNDERFLOOR HEATING AND COOLING systems.LEWIS® Dovetailed metal decking solutions are used in a range of applications includingrenovations and…

View AllChat Live

Hi you're speaking to Dave, how can I help.Website by Indigo

This website uses cookies. To see how this affects you, please read our cookie policy. -