We are often also asked what happens if the services running within the floor zone need to be accessed to effect repairs, this is difficult with a concrete floor to go in from the top and the recommendation is to access them through the ceiling. This advice also works for timber floors as to access through a timber floor board usually means cutting off the lips that hold them together and introduces further opportunities for movement and noise. We have all be in old houses where the plumber has added pipework for a central heating upgrade and there are those spots in the floor that flex and squeak because the boards have been cut to get to the space below.

The systems are also used to create floors for underfloor heating, wet-rooms and externally as balconies and terraces. If you would like to discuss this further, please get in contact.

CDI 2024

Cow Close Barn with Heat Pump and Underfloor Heating

01st January 1970

Paul M contacted us in early 2022 to discuss the use of the Lewis Deck system following a recommendation by his Ground Source Heat Pump system installer. We worked through the drawings and provided a quote, the Lewis Deck and…

View All

2022 Has Begun and Exhibitions Are, Fingers Crossed, Back To Normal.

21st January 2022

Starting on Friday 28th January, now that COVID has magically disappeared, we are heading back on the road and will be exhibiting for a full year for the first time since 2019. Next Friday sees the first exhibition at the…

View All

Lewis Deck Brochure Content

01st January 1970

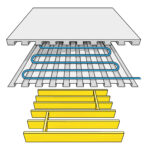

As part of a joisted floor construction, LEWIS® Dovetailed metaldecking provides a first class solution for ACOUSTICS, FIRE PROTECTION and workswell with UNDERFLOOR HEATING AND COOLING systems.LEWIS® Dovetailed metal decking solutions are used in a range of applications includingrenovations and…

View AllChat Live

Website by Indigo