- Home

- About CDI

Op-deck is a lightweight insulated floor and roof system. The advantages of composite metal deck concrete floors and traditional rib floors have been combined in this unique patented floor/ roof system.

This insulated concrete floor/ roof system (ICF) is based on traditional concrete installation but with optimal design and installation flexibility.

It is suited to insulated, high-load-bearing applications including car park roofs, intensive green-roofs and suspended high load floors including supermarkets, hospitals, etc.

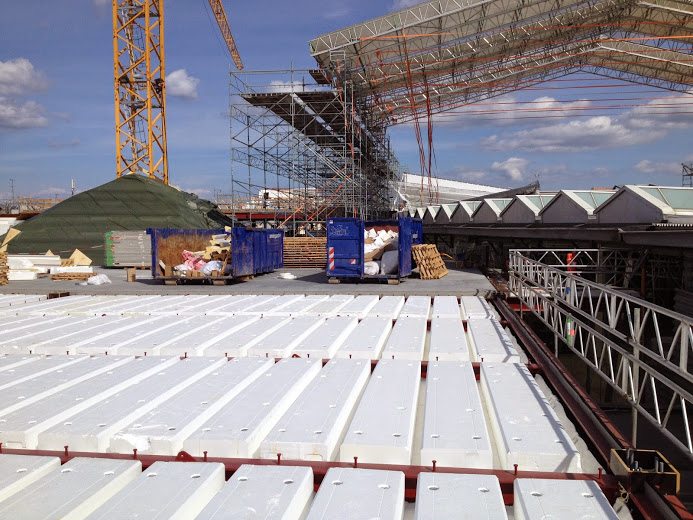

An Op-deck system can be laid on supporting structures of steel, concrete, brickwork, wood, etc. The Op-deck sandwich floor panels function as permanent shuttering for a relatively thin reinforced concrete floor with a free span of up to 10 metres maximum.

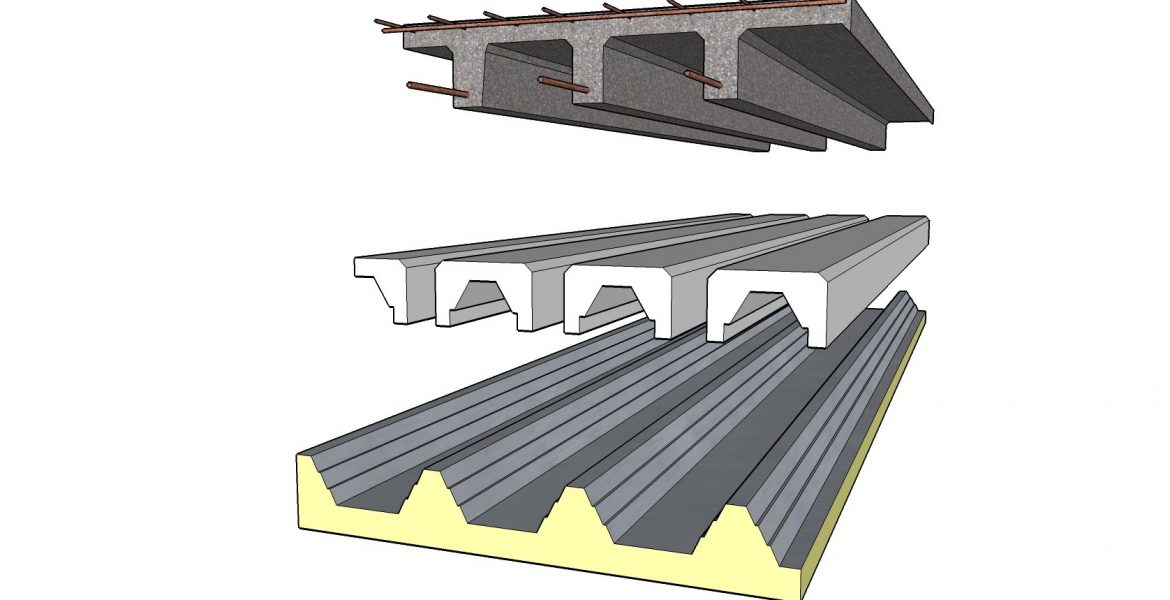

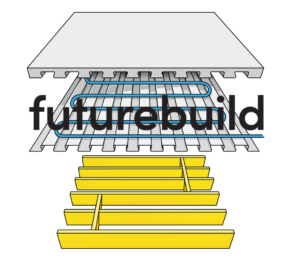

Op-deck comprises a sandwich panel made from thin profiled steel sheets with PIR foam insulation. EPS profile blocks on the sandwich panel ensure further weight reduction and turn the floor into a concrete floor of the T-beam principle (concrete rib floor).

Both components, the sandwich panels and the EPS profile blocks are installed on site. The result, after the reinforcement and concrete have been applied, is a lightweight insulated concrete floor with a large free span, small constructional height and a smooth white (RAL 9002) underside of flat sheeting, which functions as a ceiling. It is possible to include under floor heating or a complete energy management system in the Op-Deck insulated concrete floor.

Op-Deck Insulated Roof System The Op-Deck System:

- Thickness of finished concrete floor from 250 mm.

- Low own weight (from 190 kg/m2).

- Free span up to 10m.

- High permissible load (Prep).

- High bearing capacity at point load (Prep).

- Flexible system construction.

- Fire-resistant (Resistance to Fire Penetration and Fire Transfer) = 60 minutes.

- Insulating floor (Rc > 4 [m2.K/W]).

- Strut-free installation (max. 5.5m).

- Simple and fast installation.

- Easy logistics at the building site.

Op-deck sandwich floor panels and the EPS profile blocks are simple to process. An installation procedure is available. Optionally specialized application companies are available to install the Op-deck insulated concrete floors.

If you have any questions regarding the system please contact our technical team.

"Using Op-Deck meant that we could incorporate a car park on the roof of the store as we were struggling for space to hit the planning requirements on the ground"

Tom Parsons

Op-Deck sandwich floor panels and EPS profiled insulation blocks are quite simple to install, the fixing details are available on request. If required we can arrange installation through a nominated specialist contractor.

Op-Deck design software has been specially developed for the system to provide details of the optimum cross section based upon performance and design details provided by the client. As well as providing a load bearing structural floor Op-Deck provides up to a 60% reduction in weight against other floor systems. As a result the total cost of a project can be reduced considerably.

Case Studies

Self Build & Renovations

FAQs22

Ask CDI a Question

Ask CDI a Question-

Q

What are the Lewis Deck sheet sizes?

AQ: What sheet sizes are held in stock for delivery within a few days after order? A: We stock 2500mm and 1300mm sheets. These are all 630mm wide and 16mm deep. Deliveries are made via the pallet network directly to site. The smaller sheets are aimed at small bathroom renovation projects and can be supplied in small numbers via TNT. 2.5* and 1.3m sheets allow for the 100mm overlap to occur over a joist, with joist centres being either 300mm, 400mm, 600mm, 800mm*, 1200mm and 2400mm*. (*2.5m sheet only) For larger projects we are able to produce bespoke sheet sizes if required, please get in contact to discuss other options for sheet sizes.

-

Q

Why don't my Lewis sheets interlock like they do in the video?

AQ: Why don't my sheets interlock like they do in the video? A: The sheets have two sides (one printed, one plain), the dovetails on either side are different widths, it is then necessary to alternate the sheets print up and then print down.

QIs this a question?

AIf it is, this is an answer.

Latest Blog

CDI 2024

Cow Close Barn with Heat Pump and Underfloor Heating

01st January 1970

Paul M contacted us in early 2022 to discuss the use of the Lewis Deck system following a recommendation by his Ground Source Heat Pump system installer. We worked through the drawings and provided a quote, the Lewis Deck and…

View All2022 Has Begun and Exhibitions Are, Fingers Crossed, Back To Normal.

21st January 2022

Starting on Friday 28th January, now that COVID has magically disappeared, we are heading back on the road and will be exhibiting for a full year for the first time since 2019. Next Friday sees the first exhibition at the…

View AllLewis Deck Brochure Content

01st January 1970

As part of a joisted floor construction, LEWIS® Dovetailed metaldecking provides a first class solution for ACOUSTICS, FIRE PROTECTION and workswell with UNDERFLOOR HEATING AND COOLING systems.LEWIS® Dovetailed metal decking solutions are used in a range of applications includingrenovations and…

View AllChat Live

Hi you're speaking to Dave, how can I help.Website by Indigo

This website uses cookies. To see how this affects you, please read our cookie policy.