- Home

- About CDI

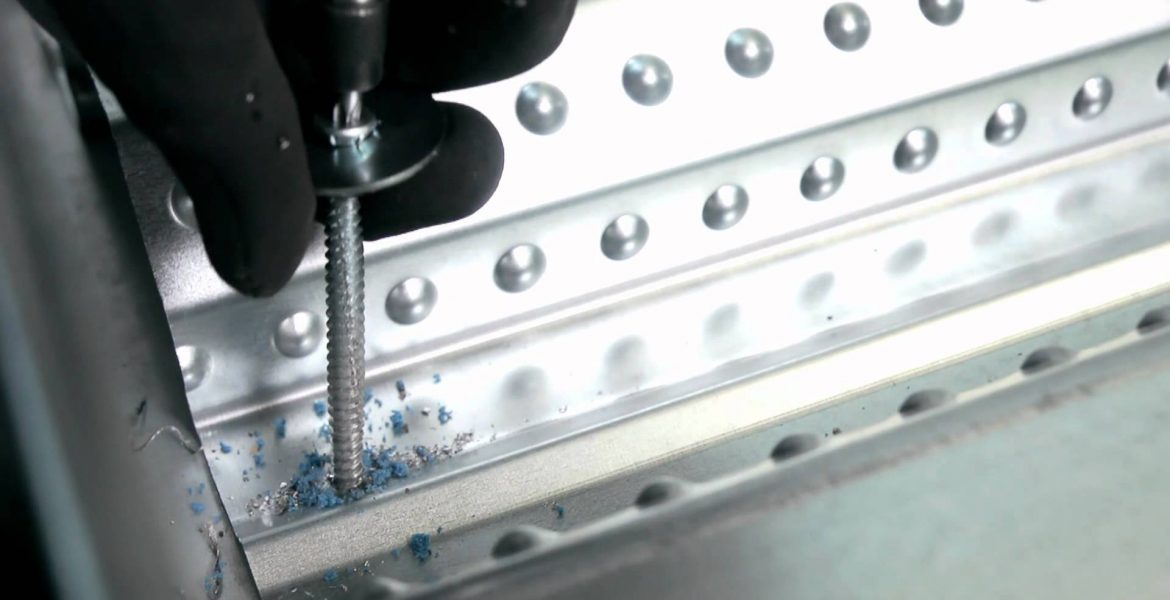

Hody profiled steel sheets have a modified trapezium shaped profile of 60 mm in height and intended for constructing, so-called, ‘low’ composite steel decking.

The finished concrete floor is between 110 mm – 290 mm high and Hody trapezium sheets can be used on free spans of up to 8 metres over the bearing construction.

Hody composite steel decking consists of a specially rolled trapezium-shaped steel sheet which functions as permanent shuttering for the relatively thin and lightweight concrete floor. This provides an extremely strong, stable and fire resistant structural floor construction which is very cost effective.

During the curing process of the concrete the trapezium sheets act as the shuttering that transfers the weight of the concrete and the assembly load to the bearing construction. When the concrete is fully cured the Hody sheets, often with supplementary reinforcement, create a well engineered structural floor solution. The sheets can be provided with interior (KID) polyester or PVDF coatings in RAL colours on the underside.

The sheets profile has a modified geometry which allows for an optimal pouring load and makes sure the combination of the sheets and the concrete allows for the highest possible load bearing capability of the floor.

The sheets have been successfully installed on new build structures, renovations, ground floor and upper levels, mezzanine floors, walkways, cantilevers as well as heavy civil projects such as bridges.

Popular uses:

- Conversions and renovation of existing properties

- Mezzanine floors

- IFD Projects

- Bridges

- Modulair building

- Sustainable constructions

- Ground floors and structural floors

- Raised floors

- Overhanging floors

- Permanent shuttering

- Industrial, Flexible and Demountable (IFD) Building projects

A detailed technical manual is available providing extensive instructions for the installation of the system and the fixing of accessories such as the profiled infill sections in PE or rockwool, galvanised steel edges and/ or end profiles, mesh requirements for increased fire resistance, upper reinforcement and concrete thickness etc.

The Hody composite floors are extensively tested by TNO-Building and Construction Research in Delft, Netherlands. Further calculations, design principles and tables have been extended by the Dutch Ingenieursburo Bartels b.v. and everything was based on Eurocode 4.

If required we can make the calculations and draw up the plans which are needed to approved by the competent authorities before work starts on site.

Should you have any further queries please contact our technical team.

Specification clauses of the Hody composite floor system are available in NBS Plus.

Case Studies

Self Build & Renovations

FAQs22

Ask CDI a Question

Ask CDI a Question-

Q

What are the Lewis Deck sheet sizes?

AQ: What sheet sizes are held in stock for delivery within a few days after order? A: We stock 2500mm and 1300mm sheets. These are all 630mm wide and 16mm deep. Deliveries are made via the pallet network directly to site. The smaller sheets are aimed at small bathroom renovation projects and can be supplied in small numbers via TNT. 2.5* and 1.3m sheets allow for the 100mm overlap to occur over a joist, with joist centres being either 300mm, 400mm, 600mm, 800mm*, 1200mm and 2400mm*. (*2.5m sheet only) For larger projects we are able to produce bespoke sheet sizes if required, please get in contact to discuss other options for sheet sizes.

-

Q

Why don't my Lewis sheets interlock like they do in the video?

AQ: Why don't my sheets interlock like they do in the video? A: The sheets have two sides (one printed, one plain), the dovetails on either side are different widths, it is then necessary to alternate the sheets print up and then print down.

QIs this a question?

AIf it is, this is an answer.

Latest Blog

CDI 2025

Is Underfloor Heating Compatible With Carpet?

11th October 2024

At Every Exhibition We Get Asked Can You Have Underfloor Heating With Carpet? Hopefully here we explain why the answer to that is YES. With carpet providing a soft, luxurious feel to your home many people ask whether underfloor heating and carpet can go…

View AllCow Close Barn with Heat Pump and Underfloor Heating

26th May 2023

Paul M contacted us in early 2022 to discuss the use of the Lewis Deck system following a recommendation by his Ground Source Heat Pump system installer. We worked through the drawings and provided a quote, the Lewis Deck and…

View All2022 Has Begun and Exhibitions Are, Fingers Crossed, Back To Normal.

21st January 2022

Starting on Friday 28th January, now that COVID has magically disappeared, we are heading back on the road and will be exhibiting for a full year for the first time since 2019. Next Friday sees the first exhibition at the…

View AllChat Live

Hi you're speaking to Dave, how can I help.Website by Indigo