- Home

- About CDI

Acoustic or “soundproof” floors are the floors between two rooms of a house, upstairs and down, between flats, one over the other or between spaces of different use, for example an apartment over a restaurant.

Acoustic separating floors can simply be used to improve the comfort of the occupants, for example to reduce the noise of the kids running about upstairs in a house or to meet the requirements of building control under part E of building regulations, or the Scottish Building Warrant.

The types of sound that are considered for these types of floors are Airborne and Impact:

Airborne Sound

Airborne sound is the noise associated with speech, the TV or other sources where the sound travels through the air.

Impact Sound

Impact sound is the noise of people moving about or sources of noise directly on top of the floor, for example people walking on a floor above or a base speaker in a cinema room.

Acoustic floors aim to reduce these two types of noise.

We have a number of acoustic floor solutions available to achieve exceptionally high levels of separation between levels of a building. These can be simply high performance floors within houses to provide extra comfort and quality within the build, through to floors with the toughest performance requirements separating loud commercial spaces from residential ones.

Examples of these include venues with live music from apartments above through to cinema floors and roof spaces with building services machines installed on the finished floor.

The technical bit

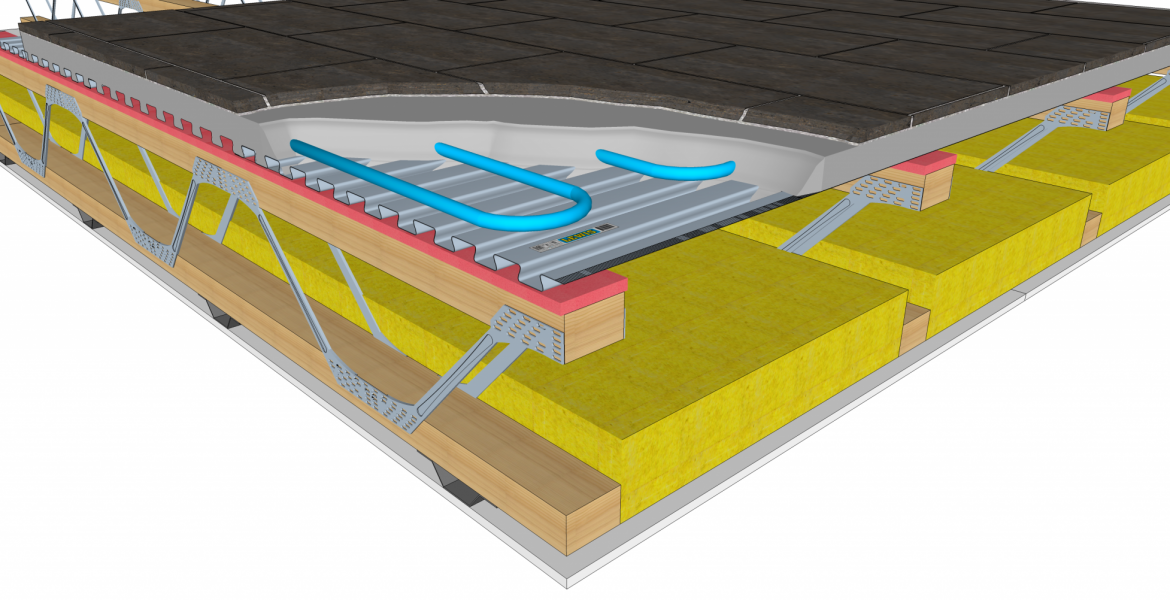

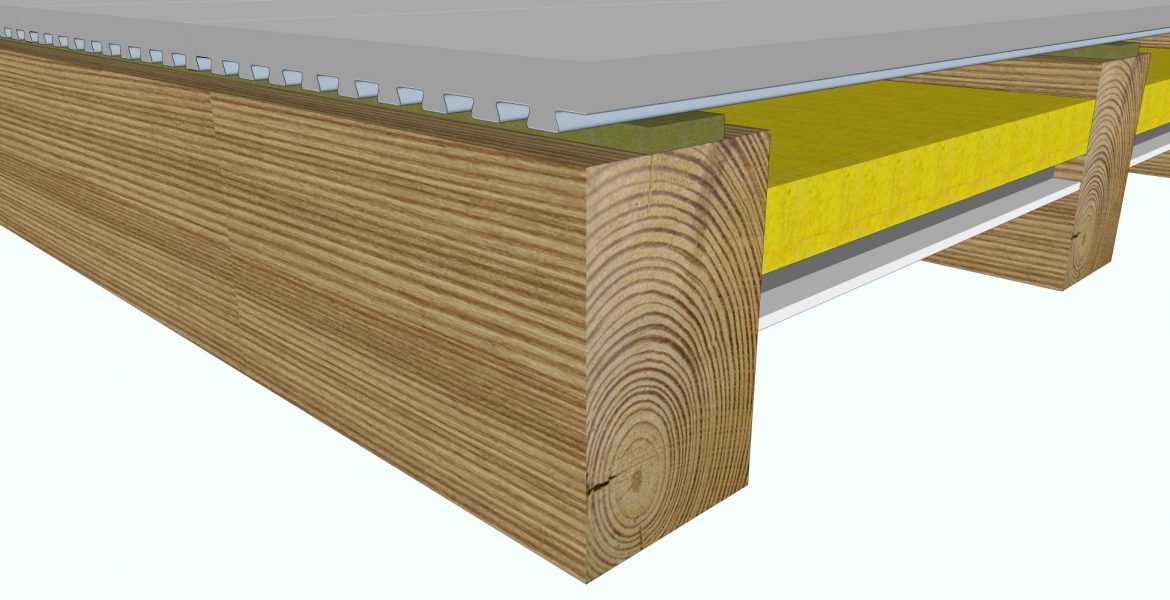

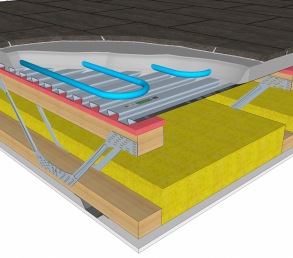

Sound is a type of vibration and it is these vibrations that pass through the structure of the building to cause nuisance, our floor systems introduce isolated stiffened mass into the building to slow/stop/dampen these vibrations. Combine this with the rest of the floor build-up including the ceiling treatment, insulation between the joists and resilient strip on top of the joists, creates a complete and very high performing acoustic solution.

Introducing this mass into lightweight floors utilising any type of timber joists helps to overcome the common low-frequency impact noise issues associated with these types of structures. This low frequency noise (typically 100Hz and lower and most annoying at around the 20Hz range) isn’t measure within Part E of building regulations, but is often a cause for complaint as it is the frequency range associated with foot fall noise from above.

Discussed in more detail here: http://www.apexacoustics.co.uk/low-frequency-impact-sound/

Available Systems

Lewis Deck

Acoustic or “soundproof” floors are the floors between two rooms of a house, upstairs and down, between flats, one over the other or between spaces of different use, for example an apartment over a restaurant. Acoustic separating floors can simply be used to improve the comfort of the occupants, for example to reduce the noise …

Read MoreMax 4

Acoustic or “soundproof” floors are the floors between two rooms of a house, upstairs and down, between flats, one over the other or between spaces of different use, for example an apartment over a restaurant. Acoustic separating floors can simply be used to improve the comfort of the occupants, for example to reduce the noise …

Read MoreCase Studies

Self Build & Renovations

FAQs22

Ask CDI a Question

Ask CDI a Question-

Q

What are the Lewis Deck sheet sizes?

AQ: What sheet sizes are held in stock for delivery within a few days after order? A: We stock 2500mm and 1300mm sheets. These are all 630mm wide and 16mm deep. Deliveries are made via the pallet network directly to site. The smaller sheets are aimed at small bathroom renovation projects and can be supplied in small numbers via TNT. 2.5* and 1.3m sheets allow for the 100mm overlap to occur over a joist, with joist centres being either 300mm, 400mm, 600mm, 800mm*, 1200mm and 2400mm*. (*2.5m sheet only) For larger projects we are able to produce bespoke sheet sizes if required, please get in contact to discuss other options for sheet sizes.

-

Q

Why don't my Lewis sheets interlock like they do in the video?

AQ: Why don't my sheets interlock like they do in the video? A: The sheets have two sides (one printed, one plain), the dovetails on either side are different widths, it is then necessary to alternate the sheets print up and then print down.

QIs this a question?

AIf it is, this is an answer.

Latest Blog

CDI 2025

Is Underfloor Heating Compatible With Carpet?

11th October 2024

At Every Exhibition We Get Asked Can You Have Underfloor Heating With Carpet? Hopefully here we explain why the answer to that is YES. With carpet providing a soft, luxurious feel to your home many people ask whether underfloor heating and carpet can go…

View AllCow Close Barn with Heat Pump and Underfloor Heating

26th May 2023

Paul M contacted us in early 2022 to discuss the use of the Lewis Deck system following a recommendation by his Ground Source Heat Pump system installer. We worked through the drawings and provided a quote, the Lewis Deck and…

View All2022 Has Begun and Exhibitions Are, Fingers Crossed, Back To Normal.

21st January 2022

Starting on Friday 28th January, now that COVID has magically disappeared, we are heading back on the road and will be exhibiting for a full year for the first time since 2019. Next Friday sees the first exhibition at the…

View AllChat Live

Hi you're speaking to Dave, how can I help.Website by Indigo

-