- Home

- About CDI

Lewis Deck to New ICF Property

Lewis Deck to New ICF PropertyOne of the best situations we find ourselves in at CDI is meeting people at a trade show and, after getting the initial “I’ve never seen this product before” comment, having the discussion about Lewis Deck that gets them over a major problem that they were having with their project.

That was the case at Ecobuild last year, when the last conversation of the whole exhibition, just as we were about to start taking the stand down, began with that phrase we get said to us so often. The gentleman in question stopped at our stand just as he was about to walk out of the exhibition when he saw our Lewis Deck model with underfloor heating pipes. The subsequent 10 minute conversation with us went through the whole system and at the end of the conversation we heard another one of the comments we get at the end of conversations, “this has just made coming here worthwhile! I’ve been looking for a way to get underfloor heating upstairs but I didn’t want to use a timber inlay system”.

Within a week we had a further conversation on the phone and had received a copy of the 1st floor layout and joist design drawing. From this we had a quotation sent out the following day along with supporting information that was requested.

Things went quiet for 6 months as the design was finalised and then in November 2017 we had received the order and the Deck and resilient strips were delivered in the last week of the month. The deck was installed without an issue and it took just over a day to lay, including some awkward cuts around a curved stairwell.

At the beginning of 2018 we decided to add a clip rail system to our range of ancillary items that we stock. Fortunately for us, and for this project, the timings were great. We arranged delivery and had them on site for the beginning of February. As this was our first project using these rails we were keen on getting comments back on their performance. These were:

“General feeling was they went down very well and although it takes a bit more time to prepare, it does lay quicker than just using p-clips. Having said this the p-clips are a must for the turn rounds and go in easily with the tech screws. The clip rail also screwed down simply and quickly using the self drill screws and, if some pre thought is applied as it goes down, some of the screws help to double up on screwing down the Lewis deck joins”.

"The Lewis Deck system worked perfectly on the ICF build system that we used. The New Lewis clip rail system worked perfectly too meaning the under floor heating installation was fitted with ease".

Julian Murfitt

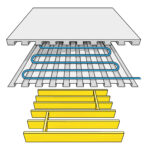

The building was constructed using ICF blocks that are to have a rendered finish. Internally the ground floor is a concrete slab and the upper floor has timber posi-joists with the Lewis Deck and resilient strips laid above. 16mm underfloor heating pipes are then clipped into our new clip rail system with a free flowing screed then poured on top, 50mm thick. This then gives 20mm cover to the heating pipes, maximising the efficiency of the whole system.

Case Studies

Self Build & Renovations

FAQs22

Ask CDI a Question

Ask CDI a Question-

Q

What are the Lewis Deck sheet sizes?

AQ: What sheet sizes are held in stock for delivery within a few days after order? A: We stock 2500mm and 1300mm sheets. These are all 630mm wide and 16mm deep. Deliveries are made via the pallet network directly to site. The smaller sheets are aimed at small bathroom renovation projects and can be supplied in small numbers via TNT. 2.5* and 1.3m sheets allow for the 100mm overlap to occur over a joist, with joist centres being either 300mm, 400mm, 600mm, 800mm*, 1200mm and 2400mm*. (*2.5m sheet only) For larger projects we are able to produce bespoke sheet sizes if required, please get in contact to discuss other options for sheet sizes.

-

Q

Why don't my Lewis sheets interlock like they do in the video?

AQ: Why don't my sheets interlock like they do in the video? A: The sheets have two sides (one printed, one plain), the dovetails on either side are different widths, it is then necessary to alternate the sheets print up and then print down.

QIs this a question?

AIf it is, this is an answer.

Latest Blog

CDI 2024

Cow Close Barn with Heat Pump and Underfloor Heating

26th May 2023

Paul M contacted us in early 2022 to discuss the use of the Lewis Deck system following a recommendation by his Ground Source Heat Pump system installer. We worked through the drawings and provided a quote, the Lewis Deck and…

View All2022 Has Begun and Exhibitions Are, Fingers Crossed, Back To Normal.

21st January 2022

Starting on Friday 28th January, now that COVID has magically disappeared, we are heading back on the road and will be exhibiting for a full year for the first time since 2019. Next Friday sees the first exhibition at the…

View AllLewis Deck Brochure Content

22nd November 2021

As part of a joisted floor construction, LEWIS® Dovetailed metaldecking provides a first class solution for ACOUSTICS, FIRE PROTECTION and workswell with UNDERFLOOR HEATING AND COOLING systems.LEWIS® Dovetailed metal decking solutions are used in a range of applications includingrenovations and…

View AllChat Live

Hi you're speaking to Dave, how can I help.Website by Indigo

-