- Home

- About CDI

Lewis Deck Brochure Content

Lewis Deck Brochure ContentAs part of a joisted floor construction, LEWIS® Dovetailed metal

decking provides a first class solution for ACOUSTICS, FIRE PROTECTION and works

well with UNDERFLOOR HEATING AND COOLING systems.

LEWIS® Dovetailed metal decking solutions are used in a range of applications including

renovations and conversions, traditional new build, timber frame, steel frame and other

off-site building systems, ICF and modular construction and mezzanine floors.LEWIS® Metal decking

The unique LEWIS® profile with its optimal geometry provides a combined action between the LEWIS® deck and the concrete/screed ensuring an extremely high load bearing capacity.

A LEWIS® composite floor consists of the LEWIS® cold rolled steel sheet covered with a relatively thin layer of C20/25 fine grade aggregate concrete or CA25F4 free flowing, self levelling, liquid screed.

During the curing period the LEWIS® deck acts as shuttering, but once the concrete/screed has cured, locking into the LEWIS® deck it forms an extremely strong, composite, structurally sound floor, i.e. it becomes reinforcement for the concrete/screed.

The use of fine grade aggregate concrete can also provide a monolithic finish to provide a “finished floor” option. The overall depth of a LEWIS® composite floor can be relatively thin – 50 mm in most cases.Common Applications

• Acoustic separating floors

• Fire resistant floors

• Bespoke Green Guide A+ rated sustainable floors

• Can easily also include underfloor heating

• Suitable sub-floor for ceramic or stone tiles, timber or laminate floor finishes.

• Can be used as a structural floor element within the building

• Mezzanine floors

• Bathrooms and wet-rooms

• Suitable for traditional, off-site construction and conversion projects

• Raised ground floorsFire Resistance

LEWIS® Dovetailed Sheeting makes it possible to design a composite floor meeting the standards without complicated details.

Generally a fire resistance of 60 – 120 minutes is achievable with all standard LEWIS® details. Fire tests certification meeting EN 13501-2 are available.More information available here.

Acoustics

Best results are achieved by laying a LEWIS® composite floor as a “floating Floor”, creating separation between the supporting floor, joists or beams with the introduction of resilient strips. Strips are laid directly to the existing timber floor or placed on top of any supporting joist/beam. The type of resilient strip is determined by the required acoustic and load bearing performance requirements. When looking at an existing floor or timber joists LEWIS® High Density Mineral Wool Strip is the most likely solution.

When looking for a higher acoustic performance or when the joist/beam spans exceed 800 mm and the load bearing capacity will exceed 2.5 Kn/m2 there are a range of specialist solutions such as LEWIS® CDM PF resilient strips or LEWIS® CDM MTA recycled rubber granulate strips. A range of acoustic strips are available for use with light gauge steel or structural steel beams – details on application.

Apart from standard domestic separating floors, LEWIS® provides exceptional solutions for bespoke acoustic floors within live music venues, night clubs, restaurants, recording studios, recreational performance studios, specialist test labs, plant rooms and many other commercial applications.More information available here.

Features

• Low dead weight

• Thin floor thickness (50 mm)

• High permissible loads

• Spans of up to 2500 mm

• High impact and airborne sound insulation

• Up to 120 minutes fire resistance

• Easy to install

• Manufactured from high quality galvanised steelWet Rooms

LEWIS® Dovetailed Sheeting composite floors are ideal for wet rooms or bathrooms in existing or new build construction. Sheets are placed on the existing floor or used as a replacement for timber decks. An exceptional waterproof wall to floor joint is created by the use of a simple damp proof membrane worked into the concrete/ screed and bonded to the walls. The floor and walls are now ready for tiling or other final finishing with no fear of movement or cracking.More information available here.

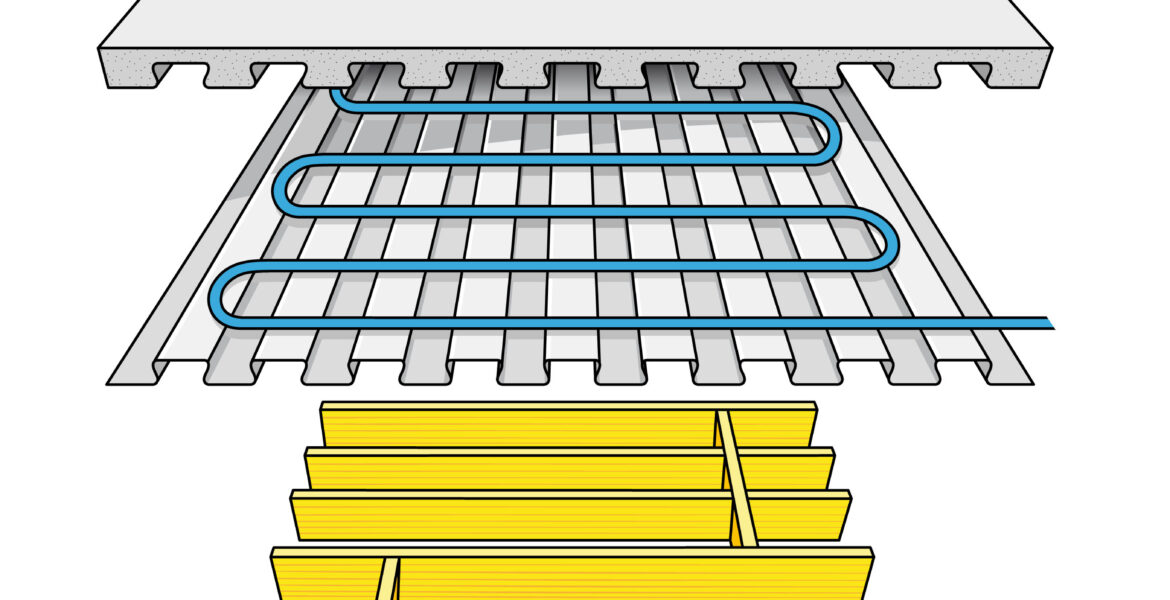

Underfloor Heating and Cooling

Underfloor heating is becoming commonplace in modern residential, commercial and public building projects.

A LEWIS® solution allows all of the efficiencies of a ground floor to be constructed on the upper floors. Pipes are secured to the upper flanges of the sheet, fixed using the LEWIS® clip or the LEWIS® rail fixing system. A minimum 20 mm of concrete/screed coverage is all that is required above the pipes. An even spread of heat is transferred from pipes to sheets and within the floor slab.• Floor thickness typically 52 mm

(with typical 16 mm pipes)

• Provides a thermal mass

• Even spread of heat eliminating

cold spots

• Easy to installMore underfloor heating information available by clicking here and here.

Renovation and Conversions

LEWIS® composite floors provide an excellent solution when looking to upgrade acoustic and fire protection performance to separating floors during the renovation or conversion of existing buildings. LEWIS® composite floors make it possible to create light weight, cost effective and easy installed “floating floor” on top of the existing floor construction.If floor to ceiling heights are an issues the existing floor boards can be removed with the LEWIS® deck then laid directly to the joists.

A standard LEWIS® floor type detail LWS-BO easily achieves the building requirements for acoustic and fire resistance for residential separating floors. Higher performance standards are easily achievable.• Easily achieves the standards for acoustic and fire

performance.

• Low dead loads

• Ideal for all renovation, conversion and new build

applications including timber frame, SIPS and ICF

building systems.Steel and Modular Construction

LEWIS® provides exceptional solutions for light gauge steel framed off-site, modular and volumetric building systems. A high load bearing capacity combined with a low dead load makes LEWIS® an ideal choice when incorporating a concrete/screed floor within LGSF or Modular systems.• Low dead load from 0.90 kN/m2

• Floor thickness from 50 mm

• High permissible loads

• Spans up to 2500 mm

• Used in floor cassettesMethod of installation

Please see the separate leaflet providing the recommended method of installation. Detailed instruction is given on the laying, jointing and fixing of the sheets, types of concrete and screed. Additional technical advice is available on request.Lewis Deck installation guide click here

Certification and Reports

The production facility is ISO 9001 and ISO 14001 certified. The LEWIS® system is fully tested, details on request.Design information

Design information including load tables are available on the last page of the pdf brochure, click here

Case Studies

Self Build & Renovations

FAQs22

Ask CDI a Question

Ask CDI a Question-

Q

What are the Lewis Deck sheet sizes?

AQ: What sheet sizes are held in stock for delivery within a few days after order? A: We stock 2500mm and 1300mm sheets. These are all 630mm wide and 16mm deep. Deliveries are made via the pallet network directly to site. The smaller sheets are aimed at small bathroom renovation projects and can be supplied in small numbers via TNT. 2.5* and 1.3m sheets allow for the 100mm overlap to occur over a joist, with joist centres being either 300mm, 400mm, 600mm, 800mm*, 1200mm and 2400mm*. (*2.5m sheet only) For larger projects we are able to produce bespoke sheet sizes if required, please get in contact to discuss other options for sheet sizes.

-

Q

Why don't my Lewis sheets interlock like they do in the video?

AQ: Why don't my sheets interlock like they do in the video? A: The sheets have two sides (one printed, one plain), the dovetails on either side are different widths, it is then necessary to alternate the sheets print up and then print down.

QIs this a question?

AIf it is, this is an answer.

Latest Blog

CDI 2024

Cow Close Barn with Heat Pump and Underfloor Heating

26th May 2023

Paul M contacted us in early 2022 to discuss the use of the Lewis Deck system following a recommendation by his Ground Source Heat Pump system installer. We worked through the drawings and provided a quote, the Lewis Deck and…

View All2022 Has Begun and Exhibitions Are, Fingers Crossed, Back To Normal.

21st January 2022

Starting on Friday 28th January, now that COVID has magically disappeared, we are heading back on the road and will be exhibiting for a full year for the first time since 2019. Next Friday sees the first exhibition at the…

View AllLewis Deck Brochure Content

22nd November 2021

As part of a joisted floor construction, LEWIS® Dovetailed metaldecking provides a first class solution for ACOUSTICS, FIRE PROTECTION and workswell with UNDERFLOOR HEATING AND COOLING systems.LEWIS® Dovetailed metal decking solutions are used in a range of applications includingrenovations and…

View AllChat Live

Hi you're speaking to Dave, how can I help.Website by Indigo

-