- Home

- About CDI

AVRO, Manchester. Listed Mill Building.

AVRO, Manchester. Listed Mill Building.It’s not everyday you get a phone call from an architect asking for help on a grade 2 listed mill building, but that is what happened to us back in April 2017 when Stephenson Studios contacted us with a problem they were having with floor to ceiling heights on their Brownsfield Mill project in Manchester.

Brownsfield Mill. Grade 2 Listed Mill Building. Their design criteria was for the existing 75mm thick timber mill boards to be retained and each of the apartments in the building would have these as an exposed ceiling. The idea was to keep the building as rustic and to retain as much of the original look and feel of the listed mill building as possible. Because of this all of the acoustic (Part E.) and fire Building Regs. (Part B.) requirements would have to be installed above the existing floor.

The drawings we were sent through identified a floor build up, on top of the mill boards, at nearly 300mm thick. This started with a self levelling compound on top of the mill boards, to level them to, and then a timber on timber solution with a final layer of cement particle board prior to the oak flooring being installed.

Original State of the Floor on Our First Visit to Site. Original Floor With Bitumen Covering. This thick floor section was causing a problem due to the original oak beams that were in place meaning the floor to ceiling heights weren’t as high as they needed to be. This design was compounded flowing the removal of the bitumen floor covering. When the mill boards were exposed and then levels were taken across each of the floors it was clear that the original design was no longer suitable for the project.

Exposed Mill Boards With the age of the building some of the mill boards were beyond repair and each of the floors needed levelling up so the use of self levelling compound and a timber/ cement board solution also became a very expensive solution. We were asked if we could come up with a solution that was able to reduce costs and time and also to be able to achieve the required acoustic and fire requirements for this type of conversion project.

Our initial thoughts on the project was to use timber ferrings, 100mm wide at 600mm centres, to lay our Lewis Deck system onto. This was reducing the number of ferrings by 50% (these were originally at 400mm centres) and it also removed 4 layers of timber/ cement board as well as the self levelling compound from the project. Following a meeting on site however, and after being able to fully talk to the deisgn team and developer about what the Lewis Deck system can do we agreed that we would look at putting the ferring strips at 1400mm centres with the Lewis Deck being laid across at these centres. Rubber granulate acoustic strips would be installed on top of each of the timbers and mineral wool insulation would then be installed between. This would allow more material to be removed from the project but crutially still hit both the acoustic and fire requirements of the project.

A test floor was commissioned, by the acoustic engineer, and built in August 2018 which passed all tests. You can see from the photos below the Lewis Deck laid at 1400mm centres for the middle section of the test with the 15mm thick rubber granulate acoustic strip laid on top of the timber ferrings. These timbers, due to the nature of the mill boards below, had to be installed individually to differing heights.

Timber Ferrings for Test Floor. Test Floor With Insulation & Lewis Deck. Screeded Test Floor. Urban Splash Website – AVRO/ Brownsfield Mill

Continue reading to find out how the installation element of the grade 2 listed mill building project went.

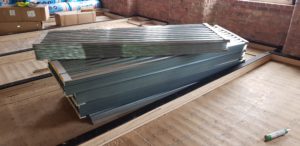

The first full delivery of Lewis Deck arrived on site at the beginning of June 2019 following on from the steel strengthening works that were being carried out on site.

Acro Props in Place During Strengthening Works. The first of the floors that were to be done was the ground floor, as the basement level was being constructed from the original concrete deck and therefore Lewis Deck wasn’t a requirement there.

1st Deck Arriving On Site. The deck was quickly installed across the whole floor in just a couple of days and the first screed pour was scheduled for the following week. The whole floor was poured using an anhydrite screed in just a few hours.

Lewis Deck to 1st Floor. Gyvlon Screed to 1st Pour. Completed 1st Screed Pour. The project continued on and the last main section of floor was poured on 19th December 2019, exactly 6 months after the first of the pours.

Dried Screed Ready For Walls To Be Installed. With the screeding works now complete the rest of the conversion is moving on at pace. Currently the internal walls as well as the 1st fix M&E elements of the project are progressing well.

Internal Stud Partitions Being Installed 1st Fix Mechanical Works Being Installed We’ll hopefully bring you more information/ photos of the buildings progress over the coming months up until the completion of the project.

This grade 2 listed mill building was a great project to work on. One that gave us a lot of challenges to overcome from the outset and one that helped overcome a number of issues that kept dropping up as the remedial works on the building progressed. We are delighted with the final result.

Developer: Urban Splash

Floor Installer: Trent Construction Services Ltd.

AVRO Brochure

Case Studies

Self Build & Renovations

FAQs22

Ask CDI a Question

Ask CDI a Question-

Q

What are the Lewis Deck sheet sizes?

AQ: What sheet sizes are held in stock for delivery within a few days after order? A: We stock 2500mm and 1300mm sheets. These are all 630mm wide and 16mm deep. Deliveries are made via the pallet network directly to site. The smaller sheets are aimed at small bathroom renovation projects and can be supplied in small numbers via TNT. 2.5* and 1.3m sheets allow for the 100mm overlap to occur over a joist, with joist centres being either 300mm, 400mm, 600mm, 800mm*, 1200mm and 2400mm*. (*2.5m sheet only) For larger projects we are able to produce bespoke sheet sizes if required, please get in contact to discuss other options for sheet sizes.

-

Q

Why don't my Lewis sheets interlock like they do in the video?

AQ: Why don't my sheets interlock like they do in the video? A: The sheets have two sides (one printed, one plain), the dovetails on either side are different widths, it is then necessary to alternate the sheets print up and then print down.

QIs this a question?

AIf it is, this is an answer.

Latest Blog

CDI 2025

Is Underfloor Heating Compatible With Carpet?

11th October 2024

At Every Exhibition We Get Asked Can You Have Underfloor Heating With Carpet? Hopefully here we explain why the answer to that is YES. With carpet providing a soft, luxurious feel to your home many people ask whether underfloor heating and carpet can go…

View AllCow Close Barn with Heat Pump and Underfloor Heating

26th May 2023

Paul M contacted us in early 2022 to discuss the use of the Lewis Deck system following a recommendation by his Ground Source Heat Pump system installer. We worked through the drawings and provided a quote, the Lewis Deck and…

View All2022 Has Begun and Exhibitions Are, Fingers Crossed, Back To Normal.

21st January 2022

Starting on Friday 28th January, now that COVID has magically disappeared, we are heading back on the road and will be exhibiting for a full year for the first time since 2019. Next Friday sees the first exhibition at the…

View AllChat Live

Hi you're speaking to Dave, how can I help.Website by Indigo

-