- Home

- About CDI

Traditionally Built House, Rugby

One of the questions we constantly get asked at trade shows and over the phone is “Can we use Lewis Deck on traditional build or does it have to be on a certain type of build method?”

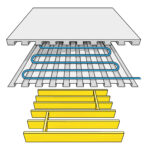

The answer is it doesn’t matter. The only design element that we look for is what is the floor support system underneath the deck? As long as there is a timber joist, a steel beam or even a concrete beam to support the Lewis Deck the system will work.

This was the case with this project. This self build project was to be traditionally built using concrete blocks with render and timber cladding providing the exterior look of the building. The main concern for the upper floor was for it to be solid, able to reduce the sound through the floor and also, due to the type of construction, it was needed to be a safe working deck that was able to hold the weight of the concrete blocks that were needed to build the upper floor of the house.

Rear of the house Blocks Stored on the Deck The Lewis Deck was exposed to the elements on this project for over 3 months while the 1st floor was build and before the roof was installed making the building watertight. In this time the deck was able to withstand the rigours of the traditional build process of blocks & mortar tubs being stored on it, materials being dropped on it, heavy foot traffic and also the English weather. As you can see from the photo above the Lewis Deck has been protected by laying the blocks on a scaffold board. This is recommended so that the decks dovetails aren’t damaged during this phase of the work.

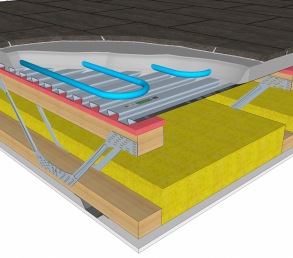

Traditional Blocks on Lewis Once the building was watertight the underfloor heating pipes and screed were installed without issue, as you can see from the photographs opposite.

When it comes to this element of work all we recommend is that the deck is checked and any heavy debris is removed from the dovetails and if needed running a vacuum cleaner over it, to remove heavy dust/ dirt, prior to the screed being laid.

The Lewis Deck was installed as soon as the build got passed 1st floor level and the joists had been installed. This gave the build a safe working deck that could support the weight of the concrete blocks without damaging it.

Tim Markham

Serivces Through Posi-Joists Lewis in a Walkway Underfloor Heating to Manifold Walkway Screeded Case Studies

Self Build & Renovations

FAQs22

Ask CDI a Question

Ask CDI a Question-

Q

What are the Lewis Deck sheet sizes?

AQ: What sheet sizes are held in stock for delivery within a few days after order? A: We stock 2500mm and 1300mm sheets. These are all 630mm wide and 16mm deep. Deliveries are made via the pallet network directly to site. The smaller sheets are aimed at small bathroom renovation projects and can be supplied in small numbers via TNT. 2.5* and 1.3m sheets allow for the 100mm overlap to occur over a joist, with joist centres being either 300mm, 400mm, 600mm, 800mm*, 1200mm and 2400mm*. (*2.5m sheet only) For larger projects we are able to produce bespoke sheet sizes if required, please get in contact to discuss other options for sheet sizes.

-

Q

Why don't my Lewis sheets interlock like they do in the video?

AQ: Why don't my sheets interlock like they do in the video? A: The sheets have two sides (one printed, one plain), the dovetails on either side are different widths, it is then necessary to alternate the sheets print up and then print down.

QIs this a question?

AIf it is, this is an answer.

Latest Blog

CDI 2024

Cow Close Barn with Heat Pump and Underfloor Heating

01st January 1970

Paul M contacted us in early 2022 to discuss the use of the Lewis Deck system following a recommendation by his Ground Source Heat Pump system installer. We worked through the drawings and provided a quote, the Lewis Deck and…

View All2022 Has Begun and Exhibitions Are, Fingers Crossed, Back To Normal.

21st January 2022

Starting on Friday 28th January, now that COVID has magically disappeared, we are heading back on the road and will be exhibiting for a full year for the first time since 2019. Next Friday sees the first exhibition at the…

View AllLewis Deck Brochure Content

01st January 1970

As part of a joisted floor construction, LEWIS® Dovetailed metaldecking provides a first class solution for ACOUSTICS, FIRE PROTECTION and workswell with UNDERFLOOR HEATING AND COOLING systems.LEWIS® Dovetailed metal decking solutions are used in a range of applications includingrenovations and…

View AllChat Live

Hi you're speaking to Dave, how can I help.Website by Indigo

This website uses cookies. To see how this affects you, please read our cookie policy. -