- Home

- About CDI

Ian Larnach Associates were formed by Ian Larnach in 2002 and were dedicated to Constructing Excellence and Egan Principles. Its intention was to drive forward with the introduction and delivery of new innovative products, systems and new ways of working from within the supply chain.

From early involvement with projects it provided a valuable service to the client, architects and engineers, working as part of the team to overcome specific product related issues. The companies ethic was to work hard ensuring that it successful and consider close involvement with projects as a vital ingredient. That always remained a priority on its part.

It had a proven track record with strong sustainable working relationships within the client client base, many of which still have a working relationship with CDI. It worked closely with designers, engineers, contractors, house builder’s, local authorities and RSL’s, assisting not only in the delivery of new methods of construction but also driving out waste. ILA strived to deliver innovation as the company strongly believe this was as still is an essential ingredient to continual success and prosperity – for any company, large or small.

The Code for Sustainable Homes was a major challenge to designers and developers alike. As Code Assessors ILA was able to assist with design issues and provide the necessary assessments to achieve accreditation.

To achieve its objectives Ian, and then Chris as well when he joined, networked at all levels within the supply chain, covering a vast cross section of specialist products& systems. By working closely with specialist manufacturers (each with their own range of innovative solutions) it allowed ILA to offer advice at various stages of the construction cycle. By drawing on the un-tapped wealth of expertise available from our supply chain associates ILA was able to provide access to resource above and beyond the normal capability of its clients.

Ian has a vast supply chain experience with over 36 years in the Construction Industry. Prior to setting up ILA he spent 26 years as a Builders Merchant.

The early years of his career Ian worked with JT Atkinson & Sons, Hartlepool, an independent heavy side Builders Merchant with six regional depots, progressing through the ranks to Depot and then Regional Manager before setting up JTA’s first Contracts Division.

In 1990 Ian moved on to join James Burrell Builders Merchants based in Gateshead as Divisional Manager to assist the company with there ambitious expansion programme. Firstly opening up new depots and trading areas in Teesside and York and then moving to head office as Business Development Director. In 1999, following the Egan report, Ian began to research the rapidly changing procurement methods sweeping through the industry and set about to produce a detailed action plan enabling James Burrell to be at the forefront of ‘Strategic Partnering within the Supply Chain’. As result James Burrell’s are now widely respected on a national basis and considered by many to be the market leaders with this style of innovative approach.

In 1999 Ian was elected as Chairman of the Builders Merchants Federation North East and during his two year stint in the chair spent as much time as possible encouraging BMF members to change working practices and embrace news ways of working. In 2000 he became involved with Construction Industry Best Practice Programme becoming the first Builders Merchant to join the Movement for Innovation (M4i). In August 2000 he was invited to join the inaugural board of Constructing Excellence North East.

Ian is married with two children, five grandchildren and resides in Spennymoor, County Durham in his native North East. Ian has always been a keen sportsman, representing his county at Football and Athletics as a schoolboy before a short career as a Professional Footballer. Ian still plays competitive sport but nowadays this only stretches to golf!

Ian retired fully from CDI in the early part of 2016 to look after his health following a second Cancer diagnosis and spends a lot of his time raising funds for charity through Ian Larnach Cancer Care Charities. Over the years Ian has raised tens of thousands of pounds for good causes and this figure continues to rise.

Case Studies

Self Build & Renovations

FAQs22

Ask CDI a Question

Ask CDI a Question-

Q

What are the Lewis Deck sheet sizes?

AQ: What sheet sizes are held in stock for delivery within a few days after order? A: We stock 2500mm and 1300mm sheets. These are all 630mm wide and 16mm deep. Deliveries are made via the pallet network directly to site. The smaller sheets are aimed at small bathroom renovation projects and can be supplied in small numbers via TNT. 2.5* and 1.3m sheets allow for the 100mm overlap to occur over a joist, with joist centres being either 300mm, 400mm, 600mm, 800mm*, 1200mm and 2400mm*. (*2.5m sheet only) For larger projects we are able to produce bespoke sheet sizes if required, please get in contact to discuss other options for sheet sizes.

-

Q

Why don't my Lewis sheets interlock like they do in the video?

AQ: Why don't my sheets interlock like they do in the video? A: The sheets have two sides (one printed, one plain), the dovetails on either side are different widths, it is then necessary to alternate the sheets print up and then print down.

QIs this a question?

AIf it is, this is an answer.

Latest Blog

CDI 2024

Cow Close Barn with Heat Pump and Underfloor Heating

01st January 1970

Paul M contacted us in early 2022 to discuss the use of the Lewis Deck system following a recommendation by his Ground Source Heat Pump system installer. We worked through the drawings and provided a quote, the Lewis Deck and…

View All2022 Has Begun and Exhibitions Are, Fingers Crossed, Back To Normal.

21st January 2022

Starting on Friday 28th January, now that COVID has magically disappeared, we are heading back on the road and will be exhibiting for a full year for the first time since 2019. Next Friday sees the first exhibition at the…

View AllLewis Deck Brochure Content

01st January 1970

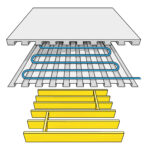

As part of a joisted floor construction, LEWIS® Dovetailed metaldecking provides a first class solution for ACOUSTICS, FIRE PROTECTION and workswell with UNDERFLOOR HEATING AND COOLING systems.LEWIS® Dovetailed metal decking solutions are used in a range of applications includingrenovations and…

View AllChat Live

Hi you're speaking to Dave, how can I help.Website by Indigo

This website uses cookies. To see how this affects you, please read our cookie policy. -