- Home

- About CDI

“How to Choose a Floor Structure” Article

In the recent Homebuilding & Renovation online magazine Ian Rock discusses the options when it comes to choosing a floor structure for both the ground and upper floors.

When it comes to ground floor the usual players are listed. These being beam & block, pre-cast hollowcore concrete beams and the basic concrete slab.

When it comes to the upper floors of a build Ian discusses the differences between the tradition timber joist and the newer joists on the market today, I-beams and metal web joists (commonly known as Posi-Joists or Eco-Joists).

Lewis Deck is identified as a perfect way of creating the upper floor deck without having all of the issues that a timber floor gives you.

“Timber has a tendency to suffer from shrinkage resulting in floors becoming squeaky over time, and is always potentially vulnerable to subsequent weakening from careless notching and drilling for pipe and cable runs”.

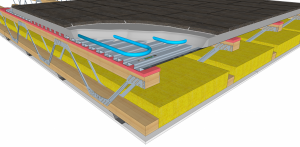

The article goes on to discuss other options available to you when thinking about your upper floor. Sound proof floors and also undefloor heating now seem to be the 2 main boxes that people are looking to tick off when thinking about their new upper floor. Lewis Deck covers both of these. With the addition of a cheap resilient material on top of the timber joist and a level of mineral wool insulation between the fllor joists, Lewis Deck easily goes passed the levels required by the current Part E of the Buildings Regulations where impact sound is concerned and with a 50mm screed floor this allows the floor to pass the airborne sound tests easily.

With 2 layers of plasterboard to the ceiling below you are also very close to achieving a 2 hour fire protection level too (for more information on this please visit the fire separation section of our website).

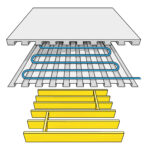

Lewis Metal Dovetailed Sheeting Deck with acoustic Sylomer resilient strips Underfloor heating is also easily taken care of with Lewis Deck. The 16mm pipes simply clip to the top surface of the deck and the (52mm) screed is then poured around the pipes. This gives the pipes total coverage with the screed meaning that when the pipes heat up they instantly transfer that heat into the screed. As the screed is a conductor of heat it then transfers this heat up to the surface enabling the room to start warming up very quickly.

Lewis Deck with UFH pipes As you can see from below this means a much faster response time than traditional “lay-in” timber or aluminium board type undefloor heating systems.

Case Studies

Self Build & Renovations

FAQs22

Ask CDI a Question

Ask CDI a Question-

Q

What are the Lewis Deck sheet sizes?

AQ: What sheet sizes are held in stock for delivery within a few days after order? A: We stock 2500mm and 1300mm sheets. These are all 630mm wide and 16mm deep. Deliveries are made via the pallet network directly to site. The smaller sheets are aimed at small bathroom renovation projects and can be supplied in small numbers via TNT. 2.5* and 1.3m sheets allow for the 100mm overlap to occur over a joist, with joist centres being either 300mm, 400mm, 600mm, 800mm*, 1200mm and 2400mm*. (*2.5m sheet only) For larger projects we are able to produce bespoke sheet sizes if required, please get in contact to discuss other options for sheet sizes.

-

Q

Why don't my Lewis sheets interlock like they do in the video?

AQ: Why don't my sheets interlock like they do in the video? A: The sheets have two sides (one printed, one plain), the dovetails on either side are different widths, it is then necessary to alternate the sheets print up and then print down.

QIs this a question?

AIf it is, this is an answer.

Latest Blog

CDI 2024

Cow Close Barn with Heat Pump and Underfloor Heating

01st January 1970

Paul M contacted us in early 2022 to discuss the use of the Lewis Deck system following a recommendation by his Ground Source Heat Pump system installer. We worked through the drawings and provided a quote, the Lewis Deck and…

View All2022 Has Begun and Exhibitions Are, Fingers Crossed, Back To Normal.

21st January 2022

Starting on Friday 28th January, now that COVID has magically disappeared, we are heading back on the road and will be exhibiting for a full year for the first time since 2019. Next Friday sees the first exhibition at the…

View AllLewis Deck Brochure Content

01st January 1970

As part of a joisted floor construction, LEWIS® Dovetailed metaldecking provides a first class solution for ACOUSTICS, FIRE PROTECTION and workswell with UNDERFLOOR HEATING AND COOLING systems.LEWIS® Dovetailed metal decking solutions are used in a range of applications includingrenovations and…

View AllChat Live

Hi you're speaking to Dave, how can I help.Website by Indigo

This website uses cookies. To see how this affects you, please read our cookie policy. -