2022 Has Begun and Exhibitions Are, Fingers Crossed, Back To Normal.

January 21, 2022

Starting on Friday 28th January, now that COVID has magically disappeared, we are heading back on the road and will be exhibiting for a full year for the first time since 2019.

Next Friday sees the first exhibition at the National Self Build Build & Renovation Centre in Swindon where we have a permanent stand (E171). Going on until late Sunday afternoon this three day event is our traditional curtain raiser, a bit like the Community Shield, to the exhibition year.

Following this we head to London, at the beginning of March, for Futurebuild. This 3 day event, from the 1st to the 3rd March, sees us setting up at ExCel, at the Docklands, where this year we’ll be at an all new stand location as the whole exhibition has had a shake up. As such our new stand location, E54, could not be more central in the hall, right next to the “Headline Partners” stand, which this year is the Construction Innovation Hub, by the RIBA Bookshop.

At the end of March, between Friday 24th and Sunday 27th, we have our biggest exhibition of the year which is the Homebuidling & Renovation Show at the NEC in Birmingham. We will be on our normal stand here, E187.

Our second NSBRC show is then on between 13th and 14th May followed then by the Built It Live, Bicester Show between the 11th and 12th June.

We then finish the exhibition year, at the moment, on the weekend of the 30th September to 2nd October with the Autumn NSBRC Show in Swindon.

There may be more events added to this list over the coming months but these are the initial ones that we’ve booked into.

We hope to see you at one of these shows.

For more information on these exhibitions please visit the Exhibitions section of our website at Events & Exhibitions – CDI (cdi-icm.co.uk)

Lewis Deck Brochure Content

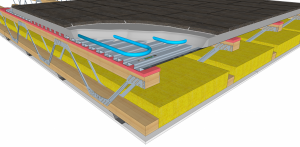

As part of a joisted floor construction, LEWIS® Dovetailed metal

decking provides a first class solution for ACOUSTICS, FIRE PROTECTION and works

well with UNDERFLOOR HEATING AND COOLING systems.

LEWIS® Dovetailed metal decking solutions are used in a range of applications including

renovations and conversions, traditional new build, timber frame, steel frame and other

off-site building systems, ICF and modular construction and mezzanine floors.

Lewis Steel Concrete Floor System

October 7, 2020

The LEWIS® Steel Frame Concrete Floor (SCF) is a patented self-supporting floor system.

The floor system features prefabricated elements consisting of a closed steel frame of cold formed C-sections that have been cast into a reinforced concrete shell, this concrete shell also forms the ceiling slab for the floor system.

The steel frame features round openings so that pipes and installations can easily be incorporated into the floor. A LEWIS® Deck top floor is placed on the steel frame. Several removable floor zones can be incorporated into the top floor depending on the level of flexibility needed in the floor system.

The LEWIS® Steel Frame Concrete Floor makes it possible to achieve free spans up to approx. 15 meters.

In addition to being used as an intermediate floor, the floor system can also be used as an insulated ground floor.

Top floor

A LEWIS® Deck floor is used as the sub-floor on top of the floor elements. This sub-floor allows for high live and concentrated loads and gives the feeling of a solid concrete floor. The LEWIS® Deck floor can be completed with a cementitious or gypsum-based screed.

For an optimal indoor climate in the building, it is possible to integrate underfloor heating into the LEWIS® Deck sub-floor. Depending on the intended purpose of the building, a completely dry floor finish can be utilised on floor elements. This floor can, for example, be made of cementitious board material. A dry top floor is also the solution when 100% flexibility of the building is required within a short operating period due to a change of function or disassembly.

Lightweight floor construction

Foundation-related costs can be reduced in new-build projects because the LEWIS® Steel Frame Concrete Floor is very light. The low weight also makes the floor system very suitable for renovating building on existing foundations.

Hi Everyone, Just A Quick Note on The Lockdown

April 15, 2020

Hi Everyone! Just a quick note to let everyone know we are still doing what we can through these tough, and weird, times.

We are working from the safety of our homes so we are able to keep giving the advice etc to people getting in touch with us about their projects, and it looks like a lot of you are using the lockdown period to crack on with your selfbuild projects!! We’ve seen a high number of calls this week from Self Builders looking to ensure that they are still able to move forward during these tough times.

We are also able to send out deliveries of Lewis Deck during this lockdown period. The pallet network is still running and we’ve worked it in a way where only one of us is going up to the warehouse to load up vehicles. Yep that’s right, Chris has drawn the short straw!!

So if you do want to get in touch we are available to chat to and also we can supply your site if needed.

We hope everyone is staying safe and if you are still working you are following the government guidelines and we hope all of the companies we deal with are able to keep going through, and after, these times. Stay strong, look after your families and we’ll hopefully speak soon.

info@cdi-icm.co.uk

Tel: (01388) 728833

Happy New Year!!

January 13, 2020

Happy New Year everyone, we hope you all had a fantastic Christmas break and are ready to get back to it.

They say time flies, we’re already into our 2nd week of January and we have been pretty busy already since we opened up again last Monday morning. We’ve already seen over 300m2 of deck leave the warehouse along with making a couple of site visits to projects where we have supplied deck too.

So what does 2020 have in store for CDI? Well we start the year, as we have done for the last few years, with an early visit down to the National Selfbuild & Renovation Centre in Swindon. This show will run from Friday 31st January until Sunday 2nd February. Paul will be on the stand for the 2 days to answer any questions you may have regarding Lewis Deck and how it will help your new self build project. March is our busiest month, and the one our wives don’t like very much, as we have our 2 biggest trade shows of the year with Futurebuild at ExCel, London (3rd – 5th) followed closely after by the Homebuilding & Renovation Show at the NEC in Birmingham (26th – 29th). Both of us will be at these shows to talk the talk.

We then jump into May and another Self Build Show in Swindon (15th – 17th) and then the Build-It Live Show in Bicester in early June (5th – 7th) where Chris will be leading the line for us.

The second half of the year is still a little up in the air as to what shows we are planning on getting involved in. We have done the Harrogate Homebuilding & Renovation Show in the past so there is a small chance we do this again and there is the odd additional show in London that just maybe we may grace with our presence.

Notes from a New Self Builder

November 1, 2018

Here at CDI we spend a lot of time at exhibitions, on the phone, writing emails and going out to site and advising people on how Lewis Deck, along with our other floor systems, should be installed and how to get the best out of them.

However, there is probably nothing better than to get advice out of someone who has just spent the last few weeks/ months building their own property and installing the deck for themselves.

This is just what, self builder, Laurence James has just done, or more accurately, is just completing. Mr James lives in Bath and back in June purchased Lewis Deck to go down on the 1st floor of his new self build property just outside of the City centre. Laurence had never used Lewis Deck before, in fact, like many self-builders, Laurence had never heard of Lewis Deck prior to seeing the system at an exhibition. After being convinced of its benefits and its suitability for his project, Laurence was happy to go ahead and the deck was delivered to site in June.

The deck was laid on top of timber “eco-joists”, that allowed Laurence to cover the 5m spans within the property and their design allowed for a very quick installation as they are very lightweight.

On top of the joists was laid the 6mm Lewis resilient rubber strips. These were simple to install too as they are self-adhesive and stick to the joists relatively easily. Around the perimeter walls our 20mm Lewis flanking strips were used. Resilient and flanking strips help with acoustic separation and the flanking strips provide, additionally, the edge expansion joint and fire integrity around the edge of the floor.

The deck, on top of this build up, took just a few days to install, after getting the hang of which way around they go, and after the underfloor heating pipes were installed, the screed was laid in a matter of hours. This gave Laurence the solid floor, with underfloor heating, that he wanted.

We spoke with self builder, Laurence earlier this week and he gave us this feedback:

“The floor system is fantastic. When we were looking to carry out this project, having a solid floor upstairs that included underfloor heating was a must for us. We had never come across Lewis Deck previously but after seeing it, we thought this was the right way to go.”

“As we are doing a lot of the work in the property ourselves, we needed something was easy to install and the system overall was. The eco-joists were light and very simple to put into place and these are great as they allowed us to install all the services in between the webs and keep the floor thickness to a minimum.”

“The Lewis Deck sheets are also light and were straight-forward enough to get up onto the 1st floor. We followed the instructions that we were given and once we had got to grips with the way the floor is orientated, to lay it was easy to install.”

“We did have a couple of issues at the beginning when trying to secure the first few sheets in place as they seemed to move ever so slightly as we added further sheets, but this seemed to disappear when additional rows were added to the floor.”

“We would also recommend getting specific “steel” cutting blades for cutting the sheets as we used normal metal discs on a grinder and we went through quite a lot before buying steel discs. Once we had these it made the job of cutting the deck much easier”

“How to Choose a Floor Structure” Article

June 28, 2018

In the recent Homebuilding & Renovation online magazine Ian Rock discusses the options when it comes to choosing a floor structure for both the ground and upper floors.

When it comes to ground floor the usual players are listed. These being beam & block, pre-cast hollowcore concrete beams and the basic concrete slab.

When it comes to the upper floors of a build Ian discusses the differences between the tradition timber joist and the newer joists on the market today, I-beams and metal web joists (commonly known as Posi-Joists or Eco-Joists).

Lewis Deck is identified as a perfect way of creating the upper floor deck without having all of the issues that a timber floor gives you.

“Timber has a tendency to suffer from shrinkage resulting in floors becoming squeaky over time, and is always potentially vulnerable to subsequent weakening from careless notching and drilling for pipe and cable runs”.

The article goes on to discuss other options available to you when thinking about your upper floor. Sound proof floors and also undefloor heating now seem to be the 2 main boxes that people are looking to tick off when thinking about their new upper floor. Lewis Deck covers both of these. With the addition of a cheap resilient material on top of the timber joist and a level of mineral wool insulation between the fllor joists, Lewis Deck easily goes passed the levels required by the current Part E of the Buildings Regulations where impact sound is concerned and with a 50mm screed floor this allows the floor to pass the airborne sound tests easily.

With 2 layers of plasterboard to the ceiling below you are also very close to achieving a 2 hour fire protection level too (for more information on this please visit the fire separation section of our website).

Are You Following Our Social Media Pages?

June 12, 2018

Are you following our Social Media pages yet?

If not you are missing out on more up to date information about what we are getting up to and where you can meet up with us. You can find us on all of the main social media networks including Facebook, Twitter, LinkedIn etc.

We post regular updates on new projects and developments that are working on so we may be working on something that is similar to what you are working on or are looking at doing. It is also another way of getting in touch with us to ask that question you have and haven’t asked yet.

Find us on Facebook at CDI

Find us on Facebook at CDI

Find us on Twitter at CDI

Find us on Twitter at CDI

Find us on YouTube at CDI

Find us on YouTube at CDI

An Introduction to CDI-ICM

May 9, 2018

During the recent Homebuilding and Renovation Show at the NEC in Birmingham Chris was able to get in front of a camera and give an introduction into CDI Innovative Construction Materials and explaining what we are all about and how our systems can benefit peoples projects in a number of different ways.

In the 5 minute interview Chris discusses what we specialise in and in what type of building these are suited to. He discusses how our systems benefit new build and renovations and how they help improve acoustic and underfloor heating performance as well as having many other key benefits.

Chris talks about how removing timber floors and introducing a concrete floor upstairs allows a floor to be stronger, less squeaky, more solid, higher performing and allows you the maximum choice when it comes to design and options on floor finishes.

More Exhibitions Coming Up!!

May 9, 2018

With Ecobuild and the Homebuilding and Renovation Show all done and dusted along with the first show at the National Self Build & Renovation Centre we’ve had a few weeks to reflect on good they were for us. The number of people we came into contact with and the general high level of discussions regarding projects from very small to very large has meant the weeks since these show we have been extremely busy.

It’s was great that each time a show ended we returned to the office with a good number of leads and a number of people already sending us information on projects they were working on. In fact in the 6 weeks since the end of the NEC’s Homebuilding and Renovation Show we’ve already supplied Lewis Deck to 2 projects and a third is due to be sent out any day.

Along with these “live” projects it was great to talk to people who are just starting out on their journey into the realm of building their own property or doing work renovating their current ones. We look forward to keeping in touch with everyone over the coming months and probably next few years while these plans and ideas turn into reality.

Find us on Facebook at

Find us on Facebook at  Find us on Twitter at

Find us on Twitter at  Find us on YouTube at

Find us on YouTube at