- Home

- About CDI

Notes from a New Self Builder

Here at CDI we spend a lot of time at exhibitions, on the phone, writing emails and going out to site and advising people on how Lewis Deck, along with our other floor systems, should be installed and how to get the best out of them.

However, there is probably nothing better than to get advice out of someone who has just spent the last few weeks/ months building their own property and installing the deck for themselves.

This is just what, self builder, Laurence James has just done, or more accurately, is just completing. Mr James lives in Bath and back in June purchased Lewis Deck to go down on the 1st floor of his new self build property just outside of the City centre. Laurence had never used Lewis Deck before, in fact, like many self-builders, Laurence had never heard of Lewis Deck prior to seeing the system at an exhibition. After being convinced of its benefits and its suitability for his project, Laurence was happy to go ahead and the deck was delivered to site in June.

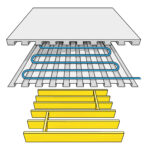

The deck was laid on top of timber “eco-joists”, that allowed Laurence to cover the 5m spans within the property and their design allowed for a very quick installation as they are very lightweight.

On top of the joists was laid the 6mm Lewis resilient rubber strips. These were simple to install too as they are self-adhesive and stick to the joists relatively easily. Around the perimeter walls our 20mm Lewis flanking strips were used. Resilient and flanking strips help with acoustic separation and the flanking strips provide, additionally, the edge expansion joint and fire integrity around the edge of the floor.

Self Builder using Lewis Deck with underfloor heating pipes in clip rails The deck, on top of this build up, took just a few days to install, after getting the hang of which way around they go, and after the underfloor heating pipes were installed, the screed was laid in a matter of hours. This gave Laurence the solid floor, with underfloor heating, that he wanted.

We spoke with self builder, Laurence earlier this week and he gave us this feedback:

“The floor system is fantastic. When we were looking to carry out this project, having a solid floor upstairs that included underfloor heating was a must for us. We had never come across Lewis Deck previously but after seeing it, we thought this was the right way to go.”

“As we are doing a lot of the work in the property ourselves, we needed something was easy to install and the system overall was. The eco-joists were light and very simple to put into place and these are great as they allowed us to install all the services in between the webs and keep the floor thickness to a minimum.”

“The Lewis Deck sheets are also light and were straight-forward enough to get up onto the 1st floor. We followed the instructions that we were given and once we had got to grips with the way the floor is orientated, to lay it was easy to install.”

“We did have a couple of issues at the beginning when trying to secure the first few sheets in place as they seemed to move ever so slightly as we added further sheets, but this seemed to disappear when additional rows were added to the floor.”

“We would also recommend getting specific “steel” cutting blades for cutting the sheets as we used normal metal discs on a grinder and we went through quite a lot before buying steel discs. Once we had these it made the job of cutting the deck much easier”

“When it came to screeding the floor we did notice that the sheets where we had starting installing had moved ever so slightly. This was not enough for us to see from above or below but when the weight of the screed hit the flanking strip at the edge of the deck there was just enough of a gap to allow some screed to seep through.”

“After pausing the screed pour we fixed the area in question with a bit of duct tape below and when we commenced the pour again we had no further issues.”

One point to note is that if you go for a free-flowing screed, as Laurence did, it comes very wet with a consistency of a gritty tomato soup. It is always recommended that you check for any potential “daylight” being visible from below before the screed is poured. If this is only spotted during the screed pour then, as Laurence did, using tape or even expanding foam is ideal for closing these gaps.

Lewis on 2 levels to create a step Laurence added “Now that the screed has dried, and the underfloor heating has been turned on, we can feel the benefits of installing Lewis Deck. The floor is solid, the underfloor heating is very effective and there is virtually no noise from upstairs to downstairs.”

Finished tiling to 1st floor bathroom “We are very happy with the way this system has worked for us and we now can’t wait to get the house fully completed”.

With thanks to Laurence and Carolyn James, Bath – 29th October 2018.

Case Studies

Self Build & Renovations

FAQs22

Ask CDI a Question

Ask CDI a Question-

Q

What are the Lewis Deck sheet sizes?

AQ: What sheet sizes are held in stock for delivery within a few days after order? A: We stock 2500mm and 1300mm sheets. These are all 630mm wide and 16mm deep. Deliveries are made via the pallet network directly to site. The smaller sheets are aimed at small bathroom renovation projects and can be supplied in small numbers via TNT. 2.5* and 1.3m sheets allow for the 100mm overlap to occur over a joist, with joist centres being either 300mm, 400mm, 600mm, 800mm*, 1200mm and 2400mm*. (*2.5m sheet only) For larger projects we are able to produce bespoke sheet sizes if required, please get in contact to discuss other options for sheet sizes.

-

Q

Why don't my Lewis sheets interlock like they do in the video?

AQ: Why don't my sheets interlock like they do in the video? A: The sheets have two sides (one printed, one plain), the dovetails on either side are different widths, it is then necessary to alternate the sheets print up and then print down.

QIs this a question?

AIf it is, this is an answer.

Latest Blog

CDI 2024

Cow Close Barn with Heat Pump and Underfloor Heating

01st January 1970

Paul M contacted us in early 2022 to discuss the use of the Lewis Deck system following a recommendation by his Ground Source Heat Pump system installer. We worked through the drawings and provided a quote, the Lewis Deck and…

View All2022 Has Begun and Exhibitions Are, Fingers Crossed, Back To Normal.

21st January 2022

Starting on Friday 28th January, now that COVID has magically disappeared, we are heading back on the road and will be exhibiting for a full year for the first time since 2019. Next Friday sees the first exhibition at the…

View AllLewis Deck Brochure Content

01st January 1970

As part of a joisted floor construction, LEWIS® Dovetailed metaldecking provides a first class solution for ACOUSTICS, FIRE PROTECTION and workswell with UNDERFLOOR HEATING AND COOLING systems.LEWIS® Dovetailed metal decking solutions are used in a range of applications includingrenovations and…

View AllChat Live

Hi you're speaking to Dave, how can I help.Website by Indigo

This website uses cookies. To see how this affects you, please read our cookie policy. -